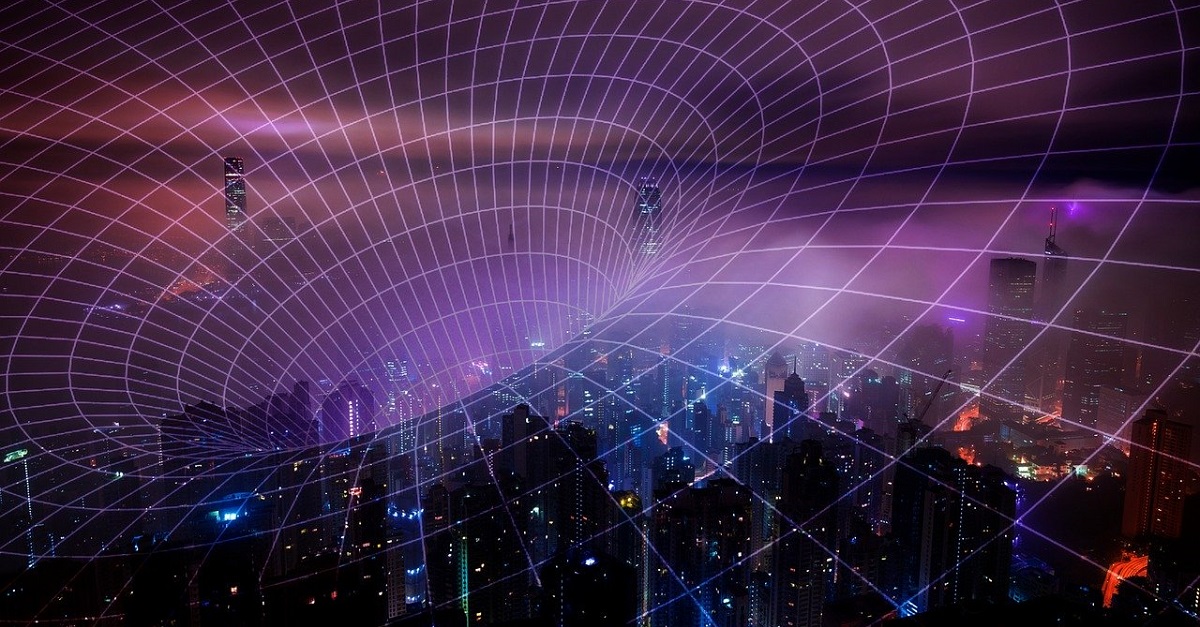

The imminent arrival of 5G-enabled manufacturing represents a defining moment in the quest for higher revenue potential. Aided by 5G networks, the manufacturing industry is expected to generate a substantial $4.6 trillion in sales.

Author Teodora Gaici | Copperberg

The benefits of this high-speed network are seemingly within the immediate reach of early adopters. Through the lens of 5G, professionals are seeing a glimmering of what the smart factory looks like: versatile, secure, automated, scalable, and highly efficient.

Yet in reality, manufacturers are quite far from a blithe ride towards 5G-empowered factories. As looming risks put the industry in a fix, the manufacturer’s grip on 5G may inexorably come unraveled.

The leap from 4G to 5G requires a prevalent paradigm change.

5G’s trajectory is somewhat askew from that of its predecessor. The unparalleled speed, connectivity, and capacity brought to the table by 5G instantly demand novel (and perhaps atypical!) rollout plans.

Industry players are actively mobilizing to develop a strategic roadmap and contest global leadership in 5G.

Only this time around, the fine line between high-reward and high-risk investments is tapering off faster than anticipated. The recent global events are temporarily curtailing manufacturing activity and yet, industry experts don’t leave the possibility of fast-forwarding 5G adoption aside.

Accelerating the deployment of 5G networks could solve the toughest challenges for supply chain management and bring manufacturing operations back under control. Or, precisely the opposite may happen: manufacturers who aren’t wary of investing in 5G could permanently reel under its disruptive impact.

It’s perhaps too soon to know if 5G should be greeted with dismay or confidence.

There is, however, a hard truth to be told: the peril is inevitably lurking in the background; after all, 5G is still in its nascent stages of deployment. If impending threats are left unattended, the first-mover advantage may translate into an outright fiasco.

Don Alusha, the Senior Analyst at ABI Research, made it abundantly clear: to capture the value at stake, professionals need to measure the impact of 5G deployments first; and if the reward is truly compelling, industry players will end up taking the risk.

In a factory setting, 4G’s successor is expected to lay the foundation for autonomous vehicles, support zero-defect manufacturing, and facilitate video-supported remote maintenance. Until such predictions come to fruition and 5G starts optimizing the usage of scarce resources, it’s important to spare a thought for the inherent risks that come with this technology.

The Tantalizing Threat of 5G Is Clomping Around

5G technology has done most of the legwork to alter the DNA of tomorrow’s smart factories.

The needle is moving—and at an extremely rapid pace.

Testing the potential of 5G investments, “from factory floor production, reconfiguration, and real time analysis, to steering a machine’s movements from a remote location,” is now a ubiquitous part of manufacturing facilities.

As the trials continue to grow in size and scope, conflicting opinions are suddenly plunging industry players into discord.

Some experts are cautious about 5G’s consequential implications in the manufacturing sector and warn about the potential security hazards brought by the influx of 5G data speeds. Others are taking a premature victory lap—and as every cautionary tale is being called out on, first-movers are inevitably spreading the false hope of improved factory output.

For all we know, a misleading claim may inevitably force the development of the smart factory into a ruinous state and heavily influence—or steer!—the course of the industry itself.

A case in point is the real-world demonstration of 5G’s capabilities. Many wireless carriers are no longer on equal ground with their competitors; they openly boast about leading the rollout of 5G networks. The only problem? The great majority of these carriers developed 5G networks using technology that sidesteps the agreed-upon standards. Similarly, AT&T launched 5G Evolution—a network that isn’t actually 5G—and needless to say, it caused quite a stir and a lot of confusion among the masses.

Will mobile carriers fall back on the promises they made and put a costly spin on the manufacturing sector?

Early adopters will be the first to know. As they pivot steadily towards 5G-enhanced manufacturing operations, they will face the inherent challenges of:

- Retrofitting 5G with existing legacy equipment while ensuring that plants will continuously bring in productivity gains.

- Custom 5G technologies that have yet to meet the vital interoperability standards and, as a result, may be difficult to update, repair, and replace.

What happens when the equipment requires replacement? The consequences will be steep: the lifecycle cost of the product might increase significantly as the competitive market decreases.

- A data-centric 5G network that brings a new set of security vulnerabilities to light.

5G puts a strong emphasis on ultra-fast data speeds; and threat actors already took notice. Given that a single weak spot that can be exploited might paralyze an organization’s ability to operate, nearly 50% of manufacturing executives lack the confidence that they are protected from external threats.

As manufacturers transfer large amounts of data across the network, all their devices—from rugged tablets on the floor to remote field gadgets—must be well-prepared against cyber attacks in order to prevent any subsequent leaks of sensitive data.

Preparing for the inevitable is a clever decision and perhaps, the only option manufacturers have at this very moment. The potholes exist; 5G will alleviate several production and logistics bottlenecks, but every efficiency gain may come at a cost.

A Rocky Start or a Permanent Disruptive Scenario?

It’s hardly a secret that 5G is a catalyst for the intelligent factory of the future.

As all the hype around this technology clears, 5G adoption may hit a wall of resistance.

The manufacturer’s ability to gauge potential risks and identify the challenges of this high-speed network ahead of time will determine their route towards an intelligible 5G horizon.

There is no room for debate: racing towards 5G is a hazard waiting to happen. If manufacturers are ill-prepared, they might end up paying the costly (and highly misleading!) price of disruption.

Reliability is a prerequisite for the development and implementation of the smart factory. Consequently, testing and validating the real potential of 5G must remain the main priority for all industry players.